More than 70 years of experience

More than 70 years of technical experience - a cable leading manufacturer in Taiwan

In product design, PEWC had developed high voltage cables including 66KV, 161KV to 345KV and established overseas turnkey project capability. In communication cable, we developed from paper insulation cable and plastic insulation cable to fiber optics cable. In electronic wire, we are the first company to develop electronic irradiated wire and insulating material technology, from irradiated XLPVC, XLPE and tubing to halogen-free XLPE wire. In enameled wire, we developed from traditional wire for coils to high-end wire for automobiles. As technical center in Taiwan, PEWC have cultivated numerous professional and technical personnel to develop overseas production sites toward globalization.

PEWC History, creating a number of first

- -The factory was established in Heping East Road, Taipei City on April 14. The original name was Pacific Wire Manufacturing Factory. For the first domestic wire and cable factory.

- -Established a research institute, added an aluminum wire manufacturing plant, and established a Daxi factory.

- -The first domestic company to obtain the certification of Teclast's 25kV cross-connected PE cable manufacturer.

- -Added electron irradiation equipment to produce irradiation line products.

- -Successfully developed the first domestic ML enameled wire with the highest temperature rating of 240 degrees.

- -The first domestic electron irradiation line was successfully developed.

- -Continuous copper bar casting plant officially produces.

- -Established a research institute, added an aluminum wire manufacturing plant, and established a Daxi plant.

- -The first domestic company to obtain the certification of Taipower’s 25kV cross-connected PE cable manufacturer.

- -Passed the certification of Taipower 69kV cross-connected PE cable type test.

- -Successfully developed the first colored enameled wire in China.

- -Developed the first grooved optical cable in China.

- -The first domestic cable factory passed the ISO 9001 standard certification.

- -The first domestic 161KV UHV cable was successfully developed and passed Taiwan Power’s finalization test.

- -Developed the first aluminum high-shielding communication cable in China to replace imported products.

- -The first domestic company to successfully develop the "High Frequency Surge Resistance Enameled Wire" product and obtain a Taiwan patent in the following year.

- -The first domestic company to set up a branch in Singapore to control the income of overseas projects.

- -Successfully developed the first low-friction flat optical cable in China.

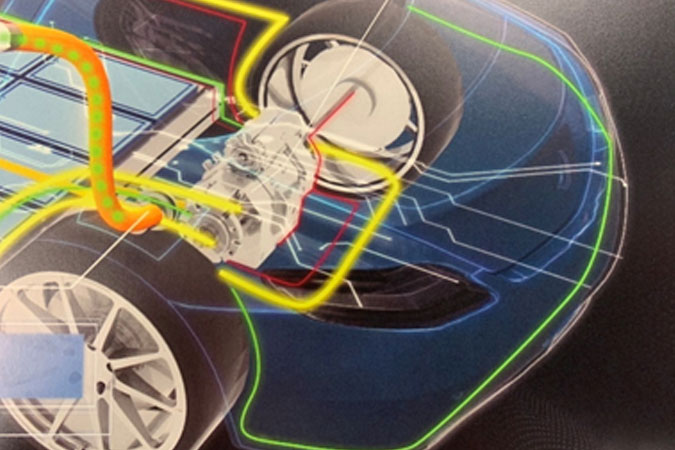

- -The first domestic company to successfully develop "flat angle enameled wire" products for electric vehicles, and obtain supply chain certification from European automakers

- -Successfully developed the first domestic low-friction flat anti-rodent optical cable

PWEC quality, from the real insistence

We insist on the purity of raw materials

Production of copper rods

Production of PVC compound

Insist on smarter production

Advanced ultra-high voltage insulated wire extrusion equipment

inspection of insulated wire interface of each shaft and degassing process of by-products ensure the service life time of the cable.

Automatic conveying system for PVC compound

First clean room in Taiwan as for cable material

IoT in Manufacturing

Adhere to a rigorous quality control system

The highest voltage level 550kV of A.C. voltage testing equipment

Five product portfolios, Fulling support national construction PEWC is the only manufacturer in Taiwan.

The largest manufacturer of building cable in Taiwan

Taiwan Railway "High Shielding Cable"

Taiwan Railways "High Shelter Cable"

Taiwan HSR "High Shielding Fire Resistant Cable"

Airport (MRT) "Signal Cable"

Support foreign public engineering Dubai, MRT, Singapore Power Grid Construction

Dubai, Macau MRT, Singapore Grid Construction

In the future, PEWC will continue to develop in electric vehicles, solar power cables, EPC projects and 5G system.

-

MoreEnamelled Wire for Electric VehicleReliable technical experience in flat-angle enamelled wires with excellent corona resistance, heat resistance, ATF oil resistance, machining resistance and high PDIV characteristics.

MoreEnamelled Wire for Electric VehicleReliable technical experience in flat-angle enamelled wires with excellent corona resistance, heat resistance, ATF oil resistance, machining resistance and high PDIV characteristics. -

MoreSolution to Green EnergyFull range of solar cable (PV cable) certified by TUV/EN and UL with superior characteristics such as UV resistance, oil resistance and flame retardant. Durable in harsh environments and widely used in major green energy projects.

MoreSolution to Green EnergyFull range of solar cable (PV cable) certified by TUV/EN and UL with superior characteristics such as UV resistance, oil resistance and flame retardant. Durable in harsh environments and widely used in major green energy projects. -

MoreProduct for 5G infrastructureNewly developed 4K HD video coaxial cable for 5G mobile communication, large-capacity multimedia information can be transmitted and downloaded in a very short time, allowing consumers to enjoy the visual experience of ultra-high-resolution images.

MoreProduct for 5G infrastructureNewly developed 4K HD video coaxial cable for 5G mobile communication, large-capacity multimedia information can be transmitted and downloaded in a very short time, allowing consumers to enjoy the visual experience of ultra-high-resolution images.