Electric Vehicle

The future trend of new energy vehicles

In the future, under the crisis of global oil reserves, greenhouse effect and environmental pollution, it is clear and irreversible to switch from internal combustion engine to drive motor for vehicle power.

Due to the impact of the epidemic, global vehicle sales in 2020 were less than 70 million units, but electric vehicle sales increased instead of decreasing, with 2.5 million units sold.

Electric vehicles are expected to continue to grow at a significant compound annual growth rate in the future.The indispensable drive motor in the new energy vehicle system.

Due to the impact of the epidemic, global vehicle sales in 2020 were less than 70 million units, but electric vehicle sales increased instead of decreasing, with 2.5 million units sold.

Electric vehicles are expected to continue to grow at a significant compound annual growth rate in the future.The indispensable drive motor in the new energy vehicle system.

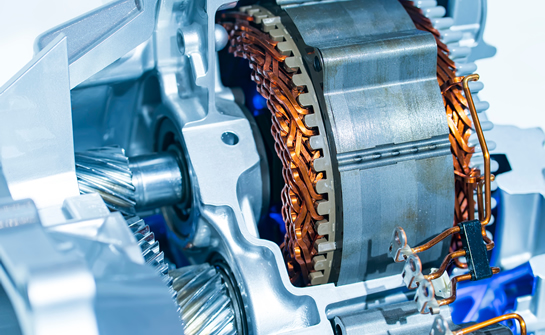

The indispensable drive motor in the new energy vehicle system

Advantages of replacing round enameled wire with rectangular enameled wire for new EV driving motors.

- ➤Higher occupation ratio of stator coil

- ➤Higher loading current and motor output power

- ➤Better motor heat dissipation and lower temperature rise

- ➤Lower manufacturing cost

Advantages of PEWC's rectangular enameled wire for new electric vehicles

Advantages of replacing round enameled wire with rectangular enameled wire for new EV driving motors.

- ➤PEWC has more than 70 years of professional enameled wire production technology and experience, and has been honored with several quality certifications with long-term trusted and adopted by customers.

- ➤Adopt the most advanced and professional rectangular enameled wire machine in Europe for production and introduce precise online machine to monitor the quality to ensure the uniformity and stability of products.

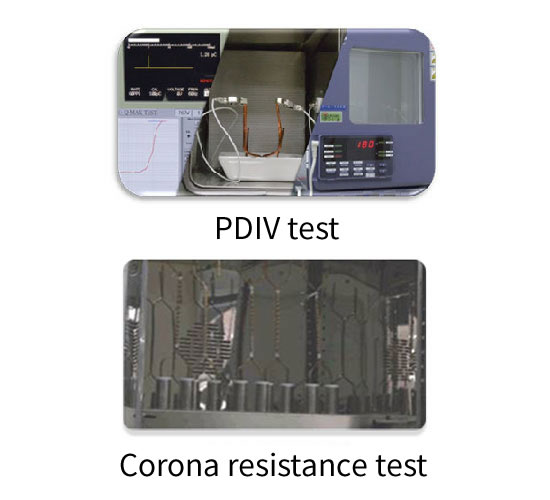

- ➤PEWC has the most complete rectangular enameled wire inspection equipment, such as corona resistance, PDIV, ATF, etc., to ensure that the quality of each item meets customer requirements.

- ➤PEWC has the certification of IATF 16949:2016, ISO-9001 and ISO-14001.

Quality items

Taidian product advantages

Quality items

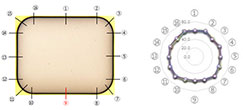

Size

(cross section)

(cross section)

Excellent thickness-to-thin ratio and uniformity

Quality items

Corona resistance test

Inorganic nanometer has good dispersibility and long life

Quality items

Flexibility

After bending the 2X rod diameter into S shape,

The film does not crack

The film does not crack

Quality items

Adhesion

After the film is cut and stretched 15%,

The film has excellent adhesion

The film has excellent adhesion

Quality items

Solderability

TIG spot welding, no blistering or color loss of the coating film

Quality items

PDIV test

Material formula with lower dielectric rate

(Film thickness<100μm,PDIV>1500Vp)

(Film thickness<100μm,PDIV>1500Vp)

Quality items

ATF test

ATF oil closed type (0.5% water content)

Test, appearance, flexibility, BDV

Test, appearance, flexibility, BDV

Film no damage

Film no crack

PEWC rectangular enameled wire for driving motor can provide:

- ➤Excellent corona resistance to extend the life of motor

- ➤Increase partial discharge initial voltage(PDIV0 to reduce the possibility of partial discharge

- ➤Good compatibility with cooling oil.

- ➤Strong enough for new electric vehicles to prevent motor from short circuit

Product Video

Download Product Catalog